The end of fiberglass?

In the era of ecological transition, fiberglass and carbon fiber remain pollutants in the composition of modern boats. Boat manufacturers have envisioned ecological alternatives.

Can these technical innovations align with the expectations of the boating industry?

Are these boats just as performance-oriented?

We-Explore

Ecology can go hand in hand with performance, as demonstrated by the sailboat We Explore, which came in second in the 2022 Route du Rhum. This boat is the result of collaboration between the design firm Kaïros and the engineers at MerConcept. To reduce the environmental impact of their vessel, the builders opted for bio-sourced materials. The usual fiberglass or carbon fiber was replaced with flax fiber. It only took one hectare of plants to achieve this feat. However, the engineers had to consider the main disadvantage of this material: its weight. The ecological alternative is 15% heavier than fibers resulting from petrochemical processes. Although this extra weight could be concerning in the design of a racing boat, it is not a concern for pleasure boats, as emphasized by the project engineers in an interview with Ouest France.

The ecological transition does not stop there! The interiors of modern boats are now also redesigned with new compostable materials. Among the most commonly used materials on board, aside from flax, are hemp, bamboo, basalt, and surprisingly, volcanic rock.

Cutting-edge technologies accessible to boaters?

The ecological transition does not stop there! The interiors of modern boats are now also redesigned with new compostable materials. Among the most commonly used materials on board, aside from flax, are hemp, bamboo, basalt, and surprisingly, volcanic rock.

Cutting-edge technologies accessible to boaters?

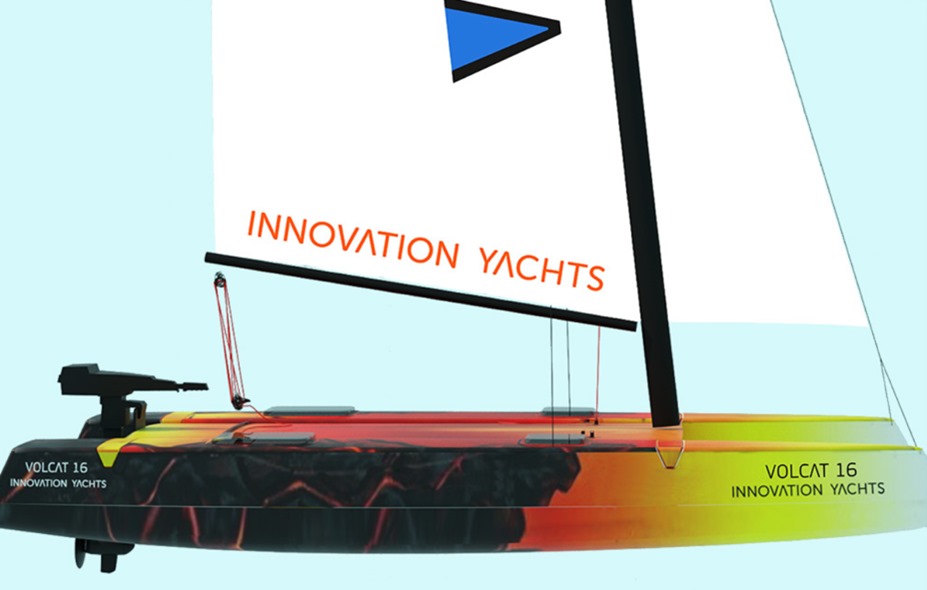

Innovation Yachts

Boat builder Innovation Yachts isn’t afraid to take risks! They are betting on the future of new technologies by embarking on the industrialization of decarbonized boat construction. The new workshop of this Vendée-based brand will set up its shipyard in spring 2024 in Les Sables d'Olonne. The goal is to create a series of sailboats using volcanic rock fiber and bio-sourced resin.

For instance, the new Volcat 16 model will be manufactured using volcanic fiber. According to the designers, the result of 14 years of research, this fiber has numerous advantages. It is hydrophobic, withstands UV rays perfectly, absorbs shocks, and has no harmful effects on the skin. These shipyards' approach is therefore ethical and virtuous, as it reduces waste production.

To date, fiberglass remains the preferred ecological alternative for boat builders due to its low cost (15% cheaper) compared to natural fibers. Considering the constant evolution of ecological legislation, it can be imagined that this material has a future.

Processes adaptable to the luxury yacht industry.

For instance, the new Volcat 16 model will be manufactured using volcanic fiber. According to the designers, the result of 14 years of research, this fiber has numerous advantages. It is hydrophobic, withstands UV rays perfectly, absorbs shocks, and has no harmful effects on the skin. These shipyards' approach is therefore ethical and virtuous, as it reduces waste production.

To date, fiberglass remains the preferred ecological alternative for boat builders due to its low cost (15% cheaper) compared to natural fibers. Considering the constant evolution of ecological legislation, it can be imagined that this material has a future.

Processes adaptable to the luxury yacht industry.

Baltic Yachts

Bcomp™ is among the leaders in offering new materials to promote eco-friendly boat construction. The company combines sustainable solutions, precision, and performance. Bcomp's solutions are bio-composite materials found in high-end boats.

To create these new fibers, flax is once again the preferred option. These materials, safe for the human body, ensure the safety of boat users as well as workers during production. Some market leaders in the boating industry and other pioneers have already opted for this solution, such as Luxe Baltic Yachts, Green Boats, and Northern Light Composites.

To create these new fibers, flax is once again the preferred option. These materials, safe for the human body, ensure the safety of boat users as well as workers during production. Some market leaders in the boating industry and other pioneers have already opted for this solution, such as Luxe Baltic Yachts, Green Boats, and Northern Light Composites.

Heading Towards the Future

These elements represent a small revolution for the sector, distinguishing themselves from petrochemical products due to their versatility. They can be used as structural components, such as the hull, as well as semi-structural components like the deck, among others. Furthermore, research is also exploring other types of materials found in nature, with numerous solutions under study. Examples include nettle fibers, resins based on potato starch, or marine bacteria. Nature provides numerous solutions for a more sustainable and eco-friendly future in the boating sector.

While the journey ahead is still long, innovations are contributing to the ecological transition of the boating industry.

These elements represent a small revolution for the sector, distinguishing themselves from petrochemical products due to their versatility. They can be used as structural components, such as the hull, as well as semi-structural components like the deck, among others. Furthermore, research is also exploring other types of materials found in nature, with numerous solutions under study. Examples include nettle fibers, resins based on potato starch, or marine bacteria. Nature provides numerous solutions for a more sustainable and eco-friendly future in the boating sector.

While the journey ahead is still long, innovations are contributing to the ecological transition of the boating industry.